Fermenter

Laboratory fermenter operation principle——Regulation of defo

Time:2023.03.14

During the fermentation process, it is common that foam is produced under conditions such as aeration and stirring because the fermentation broth has many proteins.

However, if the foam increases until it spreads to the whole tank, it will cause the fermentation broth to overflow out of the fermenter, thus increasing the possibility of contamination.Therefore, the defoaming system of laboratory fermenters is also an important part of ensuring proper fermentation.

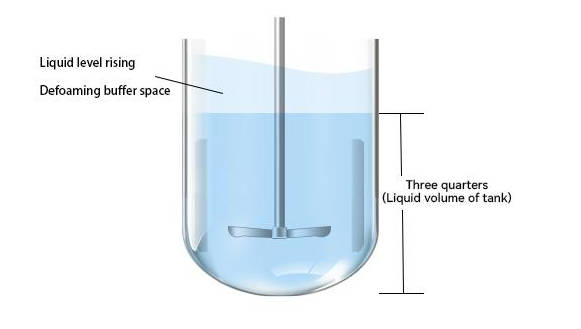

First of all, in the early stage to ensure that the amount of liquid in the tank does not exceed three-quarters of the internal space of the fermenter, the remaining space is on the one hand to fermentation aeration after the rise of the liquid level has room to spare, on the other hand, is also in order to leave a buffer time for defoaming.

Laboratory fermenters are usually defoamed by two methods, mechanical defoaming and defoamer.

Laboratory fermenters are usually defoamed by two methods, mechanical defoaming and defoamer.

A typical target defoamer, mounted slightly above the fermentation liquid level, follows the rotation of the stirring shaft as the rake teeth break up the foam.

But this way defoaming effect is also very limited, only for the fermentation of the beginning of the large bubble has a role, for the flow of foam is not effective, so the main auxiliary defoamer with the use.

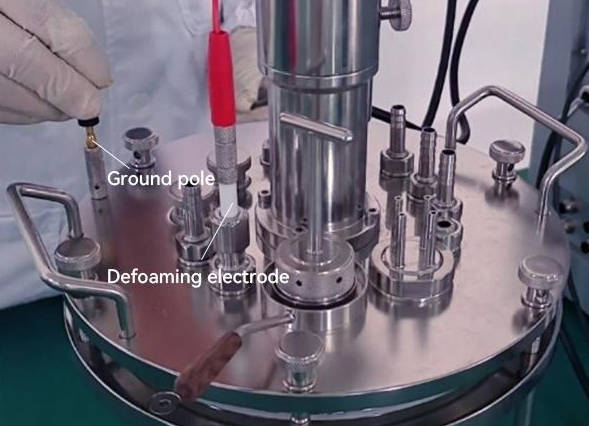

The fermenter lid will usually have a set of defoaming electrodes and a grounding post forming a line.The fermenter lid will usually have a set of defoaming electrodes and a ground pole forming a line.When the foam rises to the antifoaming electrode position, an electrical signal will be formed between the antifoaming electrodes to issue an early warning switch signal system, representing the rising foam in the tank and the need to put antifoaming agent.

When the warning signal is maintained for a number of seconds (this time is called sensitivity), after confirming the persistence of the foam, the controller sends a control switch signal to run the defoamer pump and apply defoamer to solve the problem.

When the warning signal is maintained for a number of seconds (this time is called sensitivity), after confirming the persistence of the foam, the controller sends a control switch signal to run the defoamer pump and apply defoamer to solve the problem.

Take HOLVES laboratory fermenter as an example,the highly sensitive defoamer electrode detects foam and then delivers the defoamer via a FOAM pump.To prevent over-dosing of defoamer, the HF-Control system will intermittently dose, i.e., dose for a period of time and then stop for a period of time.